一、项目背景与气候环境分析

该印刷厂位于福建中部山区,属亚热带季风气候,四季温湿变化显著:夏季高温多雨,平均气温可达28-32℃,湿度常高于80%;冬季温和湿润,平均气温在10-15℃之间。常年高湿环境易导致生产车间内闷热潮湿,不仅影响员工作业舒适度,更对印刷工艺流程及设备运行稳定性提出严峻挑战。

二、行业特性与环境要求

印刷行业对生产环境具有极高要求,主要体现在以下三方面:

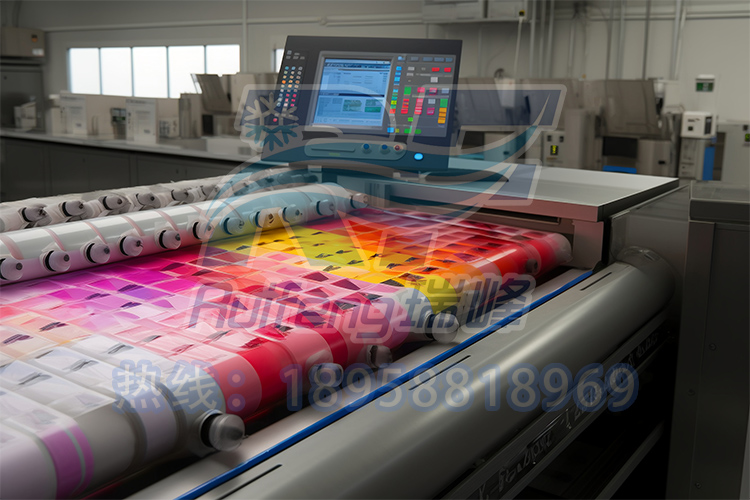

1、胶印机设备与环境关系:胶印机精密部件对温湿度极为敏感,温度过高易导致油墨黏度变化,影响印刷色泽与均匀度;湿度过大则可能引发电气部件短路或纸张吸湿变形。

2、纸张特性与环境关联:各类印刷用纸(如铜版纸、胶版纸等)具有吸湿收缩特性,环境湿度过高会导致纸张边缘翘曲,影响套印精度;湿度过低则易产生静电,造成输纸障碍。

3、印刷工艺与环境协调:温湿度波动会导致油墨干燥速度不均,可能引发蹭脏、粘连等问题,严重影响印刷品品质稳定性。

三、定制化解决方案设计

瑞峰环保制冷技术团队经现场勘查与综合分析,确立以下设计要点:

1、地理与建筑适配:山区气候湿度偏高,厂房为钢筋混凝土结构且窗户密封性较好,适合采用内循环气流组织方案,避免室外高湿空气渗透。

2、生产特性匹配:印刷过程中纸张对气流极为敏感,强直吹气流会导致纸张移位,故选用出风柔和、扩散均匀的立式轴流机型,确保气流组织平稳覆盖。

3、负荷与能效平衡:车间面积达800平方米,设备发热量大,经热负荷计算需配备10匹大功率机组,在满足制冷量需求的同时,采用变频技术实现节能运行。

四、实施方案与成效

项目采用立式双出风口轴流省电工业空调系统,通过双风口送风形成立体环绕式气流,实现车间温度均匀下降4-6℃、湿度稳定控制在55%-65%的理想范围。安装调试后:

1、印刷品套准精度提升30%,油墨干燥速度趋于稳定

2、纸张输送故障率降低40%,生产效率显著提高

3、员工夏季作业满意度调查达标率达95%以上

五、项目价值延伸

本案虽聚焦印刷行业,但其环境控制逻辑同样适用于食品加工、精密仪器装配、药品仓储等对温湿度敏感的领域。瑞峰团队通过本项目进一步积累了高精度环境调控经验,展现出跨行业、多场景的专业适配能力,为各类生产空间提供“诊断-设计-实施-优化”的全链解决方案。

1、 Project Background and Climate Environment Analysis

The printing factory is located in the central mountainous area of Fujian Province, with a subtropical monsoon climate and significant temperature and humidity changes throughout the four seasons. The summer is hot and rainy, with an average temperature of 28-32 ℃ and humidity often exceeding 80%; Winter is mild and humid, with an average temperature between 10-15 ℃. The perennial high humidity environment can easily lead to stuffiness and humidity in the production workshop, which not only affects the comfort of employees, but also poses serious challenges to the printing process and equipment operation stability.

2、 Industry characteristics and environmental requirements

The printing industry has extremely high requirements for the production environment, mainly reflected in the following three aspects:

(1). The relationship between offset printing machine equipment and environment: Precision components of offset printing machines are extremely sensitive to temperature and humidity. Excessive temperature can easily cause changes in ink viscosity, affecting printing color and uniformity; Excessive humidity may cause electrical components to short circuit or paper to absorb moisture and deform.

(2). The characteristics of paper are related to the environment: various types of printing paper (such as copperplate paper, offset paper, etc.) have moisture absorption and shrinkage characteristics. High environmental humidity can cause the edges of the paper to warp, affecting the printing accuracy; Low humidity can easily generate static electricity, causing paper feeding obstacles.

(3). Coordination between printing technology and environment: Fluctuations in temperature and humidity can lead to uneven ink drying speed, which may cause problems such as smudging and adhesion, seriously affecting the stability of printed product quality.

3、 Customized solution design

The Ruifeng Environmental Protection Refrigeration Technology Team has established the following design points through on-site investigation and comprehensive analysis:

(1). Geographical and architectural adaptation: The climate and humidity in mountainous areas are relatively high, and the factory building is made of reinforced concrete structure with good window sealing. It is suitable to adopt an internal circulation airflow organization scheme to avoid the infiltration of high humidity outdoor air.

(2). Production characteristic matching: During the printing process, paper is extremely sensitive to air flow, and strong blowing air flow can cause paper displacement. Therefore, a vertical axial flow machine with soft air outlet and uniform diffusion is selected to ensure smooth coverage of air flow organization.

(3). Load and energy efficiency balance: The workshop covers an area of 800 square meters and the equipment generates a large amount of heat. According to the heat load calculation, a 10 horsepower high-power unit is required to meet the cooling capacity requirements while using frequency conversion technology to achieve energy-saving operation.

4、 Implementation plan and effectiveness

The project adopts a vertical dual outlet axial flow energy-saving industrial air conditioning system, which forms a three-dimensional surrounding airflow through dual outlet air supply, achieving a uniform temperature drop of 4-6 ℃ and stable humidity control within the ideal range of 55% -65% in the workshop. After installation and debugging:

(1). Printing accuracy improved by 30%, ink drying speed stabilized

(2). The failure rate of paper conveying has been reduced by 40%, and the production efficiency has been significantly improved

(3). The satisfaction rate of employees' summer homework survey has reached over 95%

5、 Project Value Extension

Although this case focuses on the printing industry, its environmental control logic is also applicable to temperature and humidity sensitive fields such as food processing, precision instrument assembly, and pharmaceutical warehousing. The Ruifeng team has further accumulated high-precision environmental control experience through this project, demonstrating professional adaptability across industries and multiple scenarios, and providing a full chain solution of "diagnosis design implementation optimization" for various production spaces.

更多案例

客服热线:18958818969

服务热线:13356130717

电子邮件:ruifeng0717@163.com

公司地址:浙江省温州市平阳县万全镇紫来创业园二幢

瑞峰官网:www.wzrfhb.com