一、项目背景与概况

该厂位于深圳市——一座地处华南沿海、属亚热带季风气候的现代化工业城市。这里夏季漫长,高温高湿,月平均气温常达28-32℃,相对湿度普遍超过80%;冬季短暂温和,偶有湿冷,年降水量充沛,气候整体呈现“湿热时间长、通风需求高”的特点。在这一气候环境下,厂内生产环境的稳定控制尤为关键。

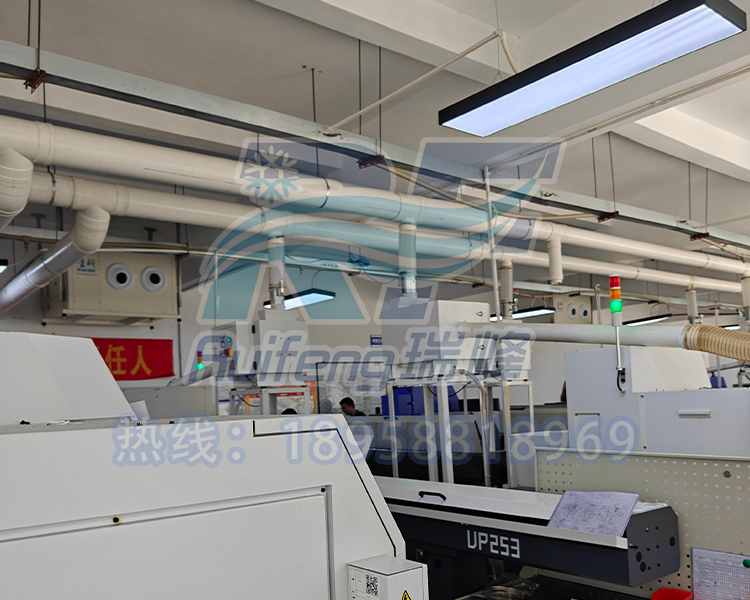

该企业专业从事高精度零部件制造,主要使用CNC走心机(数控走心机)等先进机床,为汽车制造、航空航天、医疗器械、电子产品及模具制造等行业提供关键精密部件。生产过程中,机床长时间高速运转会产生大量热量,同时精密加工对环境的温度、湿度及洁净度有较高要求。若车间环境失控,不仅影响设备精度与寿命,也可能导致零件热胀冷缩、加工误差增大,最终影响产品合格率。

厂房为多层钢筋混凝土标准工业建筑,内部空间开阔,但实际可用地面面积有限,传统落地式空调设备占用生产区域,且难以实现远距离均匀送风。因此,需设计一套既能高效降温、又不占用宝贵生产面积的通风降温方案。

二、瑞峰方案设计要点

我方技术团队经现场综合勘测与分析,重点考量以下因素:

1、地理气候环境:针对深圳高温高湿的气候特点,强调除湿与降温并重;

2、厂房建筑结构:利用混凝土结构层高优势,采用空中吊挂安装,避免占用地面作业空间;

3、设备与工艺需求:结合CNC设备发热量大、对环境波动敏感的特性,确保送风稳定、覆盖面广;

4、空间利用限制:因车间纵向空间充足但地面布局紧凑,选用大功率卧式射流蒸发冷却工业空调,该机型具备送风距离远、气流组织均匀的特点,可覆盖大面积区域,实现高效循环通风。

三、系统实施与成效

项目采用多台大功率卧式射流蒸发冷空调,沿车间顶部合理分布,形成覆盖全车间的立体空气循环系统。该方案不仅大幅降低室内温度,有效控制湿度,还通过持续新风补给改善空气质量。

实施后,车间工作环境得到显著提升:员工在夏季闷热天气下的闷热感和疲劳感明显减轻,工作舒适度与效率同步提高;同时,稳定的温湿度环境使CNC机床保持最佳运行状态,加工尺寸稳定性增强,产品良品率得到有效提升,为企业节约了因环境问题导致的返工与损耗成本。

四、项目示范意义

本工程虽实施于精密机械加工行业,但其设计理念与技术方案同样适用于其他对生产环境有严格要求的行业,例如:

1、电子半导体生产车间

2、医疗器械与制药洁净车间

3、精密仪器组装车间

4、食品冷链加工区域

5、物流仓储高温区域

同时,该方案也适用于各类结构类似的多层厂房、钢结构大空间建筑及老旧车间改造项目,具备良好的行业适配性与推广价值。

1、 Project Background and Overview

The factory is located in Shenzhen, a modern industrial city situated along the coast of southern China with a subtropical monsoon climate. The summer here is long, with high temperatures and humidity. The monthly average temperature often reaches 28-32 ℃, and the relative humidity generally exceeds 80%; Winter is brief and mild, occasionally wet and cold, with abundant annual precipitation, and the overall climate presents the characteristics of "long humid and hot time, high ventilation demand". In this climate environment, stable control of the production environment within the factory is particularly crucial.

This enterprise specializes in high-precision component manufacturing, mainly using advanced machine tools such as CNC walking machines, to provide key precision components for industries such as automotive manufacturing, aerospace, medical equipment, electronic products, and mold manufacturing. During the production process, prolonged high-speed operation of machine tools generates a large amount of heat, and precision machining requires high environmental temperature, humidity, and cleanliness. If the workshop environment gets out of control, it not only affects the accuracy and lifespan of the equipment, but may also lead to thermal expansion and contraction of parts, increased processing errors, and ultimately affect the product qualification rate.

The factory building is a multi story reinforced concrete standard industrial building with spacious interior, but the actual usable floor area is limited. Traditional floor standing air conditioning equipment occupies the production area and is difficult to achieve long-distance uniform air supply. Therefore, it is necessary to design a ventilation and cooling scheme that can efficiently cool down without occupying valuable production area.

2、 Key points of Ruifeng scheme design

Our technical team conducted a comprehensive on-site survey and analysis, focusing on the following factors:

(1). Geographical climate environment: In response to the high temperature and humidity climate characteristics of Shenzhen, emphasis is placed on both dehumidification and cooling;

(2). Factory building structure: Taking advantage of the height advantage of concrete structure, suspended installation is adopted in the air to avoid occupying ground work space;

(3). Equipment and process requirements: Combining the high heat generation and sensitivity to environmental fluctuations of CNC equipment, ensure stable air supply and wide coverage;

(4). Space utilization limitations: Due to sufficient vertical space in the workshop but compact ground layout, a high-power horizontal jet evaporative cooling industrial air conditioner is selected. This model has the characteristics of long air supply distance and uniform airflow organization, and can cover a large area to achieve efficient circulation ventilation.

3、 System implementation and effectiveness

The project adopts multiple high-power horizontal jet evaporative cooling air conditioners, which are reasonably distributed along the top of the workshop to form a three-dimensional air circulation system covering the entire workshop. This plan not only significantly reduces indoor temperature and effectively controls humidity, but also improves air quality through continuous fresh air supply.

After implementation, the working environment in the workshop has been significantly improved: employees' sense of stuffiness and fatigue in the hot and humid summer weather has been significantly reduced, and work comfort and efficiency have been synchronously improved; At the same time, a stable temperature and humidity environment keeps CNC machine tools in optimal operating condition, enhances dimensional stability, and effectively improves product yield, saving enterprises the cost of rework and loss caused by environmental issues.

4、 The significance of project demonstration

Although this project is implemented in the precision machining industry, its design concept and technical solution are also applicable to other industries that have strict requirements for the production environment, such as:

(1). Electronic semiconductor production workshop

(2). Medical Device and Pharmaceutical Cleanroom

(3). Precision instrument assembly workshop

(4). Food cold chain processing area

(5). High temperature area for logistics warehousing

At the same time, this plan is also applicable to various multi story factory buildings, steel structure large space buildings, and old workshop renovation projects with similar structures, and has good industry adaptability and promotional value.

更多案例

客服热线:18958818969

服务热线:13356130717

电子邮件:ruifeng0717@163.com

公司地址:浙江省温州市平阳县万全镇紫来创业园二幢

瑞峰官网:www.wzrfhb.com