一、项目背景与地域环境分析

1.1 项目概况

建興制衣(柬埔寨)有限公司(高棉文:ក្រុមហ៊ុន ជៀនស៊ីង គារមេនត៍ (កម្ពុជា) ឯ.ក,英文:J-STAR GARMENT (CAMBODIA) CO., LTD.)位于柬埔寨金边市郊工业区,是一家承接国际快时尚品牌及欧美日韩订单的现代化制衣企业。作为柬埔寨典型的劳动密集型产业代表,工厂雇佣大量本地员工,车间的环境质量直接影响生产效率与员工健康。

1.2 气候与产业背景

金边属热带季风气候,全年分为雨季(5-10月)与旱季(11-4月),日均气温介于28℃-35℃,平均湿度高达80%以上,高温高湿环境对厂房通风降温提出严峻挑战。柬埔寨纺织服装业与中国供应链深度关联,从面料、设备到技术管理均受益于中柬产能合作,属于“中国支撑+本地制造”的典型模式。

二、厂房结构与生产布局

2.1 建筑特征

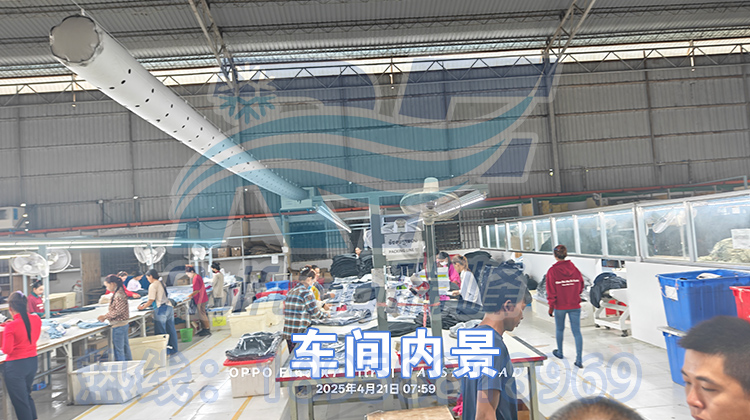

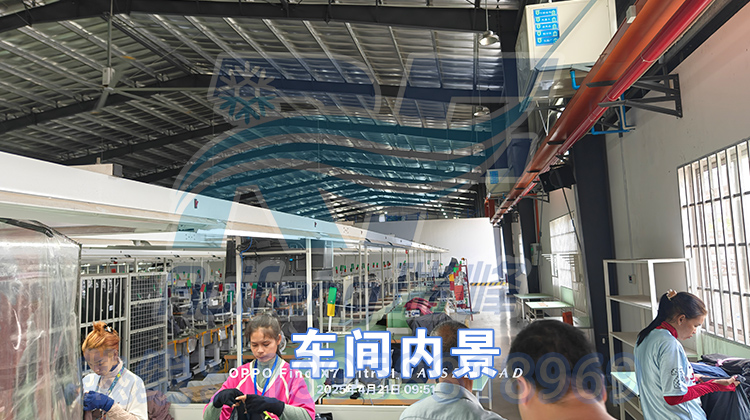

厂区由多个彩钢结构车间组成,屋顶为彩钢瓦,墙体为砖砌结构,密封性一般。本次实施车间总面积约8000平方米,层高10米,属于高大空间建筑,冷量容易向上逸散,传统通风方式难以实现有效降温。

2.2 生产工艺与车间分区

制衣流程涵盖:

2.2-1 裁床区:布料裁剪与初加工

2.2-2 缝纫区:服装缝制主力区域,人员密集,机台发热量大

2.2-3 整烫区:高温熨烫与定型作业

2.2-4 质检区:成品检验与修补

2.2-5 包装区:服装整理、贴标与装箱

各区域依据工艺流程布局,其中缝纫区占地面积最大、作业人员最多,是环境改善的重点区域。

2.3 原有通风状况

车间原安装负压风机与大功率工业吊扇,具备基础排风能力,但无法实现温度调节,夏季室内体感温度长期高于35℃,员工易出现疲劳、中暑等现象,影响生产连续性与品质稳定性。

三、瑞峰环保制冷的系统化解决方案

3.1 设计综合考虑因素

3.1-1 环境因素:热带气候全年热负荷高,湿度大,需兼顾降温与除湿;

3.1-2 建筑因素:彩钢屋顶吸热快,层高高,送风阻力大,冷量分布不易均匀;

3.1-3 设备协同:保留原有负压风机实现整体换气,新系统侧重岗位精准降温;

3.1-4 电力条件:柬埔寨电网稳定性弱,电价较高,需采用超低能耗设计;

3.1-5 维护便利:当地技术力量有限,系统需具备高可靠性与易维护性。

3.2 定制化系统设计

采用蒸发冷却+软式风管定点送风方案,核心包括:

3.2-1 适配柬埔寨电压(230V/50Hz)的高效蒸发冷空调主机;

3.2-2 抗腐蚀软式风管网络,沿车间主通道敷设,风口精准对应工位区;

3.2-3 智能控制系统,可根据区域人员密度与温湿度自动调节送风量;

3.2-4 低水位保护与水质过滤装置,适应当地水质条件,延长设备寿命。

3.3 系统运行特点

3.3-1 节能显著:较传统压缩机制冷节能70%以上,缓解当地电力压力;

3.3-2 定向降温:送风直接覆盖员工活动区域,实现“人降温而非空间降温”;

3.3-3 协同增强:原有负压风机负责整体换气,新系统提供清凉新风,形成“整体通风+局部降温”复合效果;

3.3-4 快速安装:模块化结构,两周内完成全线安装调试,不影响生产计划。

四、实施效果与客户反馈

4.1 环境指标提升

系统投运后,岗位区域温度降低5℃-8℃,相对湿度下降15%-20%,员工工作区域始终保持在28℃-30℃的舒适范围内。

4.2 生产效率与人文关怀双赢

员工流失率降低,工作专注度提升,缝纫机台日均产量提高约12%;

中暑、头晕等职业健康问题大幅减少,员工满意度显著提升;

车间整体环境改善,成为业主接待客户参观的亮点工程。

4.3 业主评价

“瑞峰提供的不仅是一套设备,更是适合热带厂房的整体环境解决方案。电费没有明显增加,员工却都说‘现在好多了’,这对我们保持产能和吸引工人非常关键。”

五、项目意义与行业启示

柬埔寨及多数东南亚国家正处在工业化快速发展阶段,厂房基础设施薄弱、电力资源紧张、高温高湿环境影响生产等问题普遍存在。本项目成功实践表明:

5.1 中国技术适配性强:针对不同国家电压、气候、建筑特点的定制化能力,是中国制造业走出去的关键优势;

5.2 节能技术是核心竞争力:在能源成本高企的地区,省电空调不仅是环境设备,更是生产成本控制工具;

5.3 系统性思维至关重要:通风降温不是简单安装设备,而应结合建筑结构、原有系统、人员动线、当地资源进行一体化设计。

瑞峰环保制冷凭借在国内众多工业场景积累的经验,正将高效、节能、可靠的通风降温解决方案输出到“一带一路”沿线国家,助力当地产业提升环境质量与可持续发展能力。

1、 Analysis of Project Background and Regional Environment

1.1 Project Overview

Jianxing Garment (Cambodia) Co., Ltd. (Khmer: ក្រុមហ៊ុនជៀនស៊ីងគារមេន៍) ពុជា) ឯ J-STAR GARMENT (CAMBODIA) CO., LTD. is located in the suburban industrial zone of Phnom Penh, Cambodia. It is a modern clothing enterprise that undertakes international fast fashion brands and orders from Europe, America, Japan, and South Korea. As a typical representative of labor-intensive industries in Cambodia, factories employ a large number of local employees, and the environmental quality of the workshop directly affects production efficiency and employee health.

1.2 Climate and Industrial Background

Phnom Penh has a tropical monsoon climate, which is divided into rainy season (May October) and dry season (November April) throughout the year. The daily average temperature ranges from 28 ℃ to 35 ℃, and the average humidity is over 80%. The high temperature and high humidity environment pose a serious challenge to ventilation and cooling in factories. The Cambodian textile and clothing industry is deeply connected to the Chinese supply chain, benefiting from the cooperation in production capacity between China and Cambodia in terms of fabrics, equipment, and technical management. It belongs to the typical model of "Chinese support+local manufacturing".

2、 Factory Structure and Production Layout

2.1 Architectural Features

The factory area consists of multiple color steel structure workshops, with a roof made of color steel tiles and walls made of brick structures, with average sealing. The total area of the workshop implemented this time is about 8000 square meters, with a floor height of 10 meters. It is a tall and spacious building, and the cooling capacity is prone to dissipate upwards. Traditional ventilation methods are difficult to achieve effective cooling.

2.2 Production process and workshop zoning

The garment manufacturing process covers:

2.2-1 Cutting area: Fabric cutting and initial processing

2.2-2 Sewing area: the main area for clothing sewing, with dense personnel and high heat generation from the machines

2.2-3 Ironing area: High temperature ironing and shaping operations

2.2-4 Quality Inspection Area: Finished Product Inspection and Repair

2.2-5 Packaging Area: Clothing sorting, labeling, and boxing

Each area is arranged according to the process flow, with the sewing area occupying the largest area and having the most workers, making it a key area for environmental improvement.

2.3 Original ventilation conditions

The workshop was originally equipped with negative pressure fans and high-power industrial ceiling fans, which have basic exhaust capabilities, but cannot achieve temperature regulation. In summer, the indoor perceived temperature remains above 35 ℃ for a long time, and employees are prone to fatigue, heatstroke, and other phenomena, which affects production continuity and quality stability.

3、 Systematic Solution for Ruifeng Environmental Protection Refrigeration

3.1 Comprehensive considerations for design factors

3.1-1 Environmental factors: Tropical climate has high heat load and humidity throughout the year, requiring a balance between cooling and dehumidification;

3.1-2 Building factors: Color steel roofs absorb heat quickly, have high floor heights, high air supply resistance, and uneven distribution of cooling capacity;

3.1-3 Equipment Collaboration: Retain the original negative pressure fan to achieve overall ventilation, and the new system focuses on precise cooling of positions;

3.1-4 Power Conditions: Cambodia's power grid has weak stability and high electricity prices, requiring ultra-low energy consumption design;

3.1-5 Maintenance Convenience: Due to limited local technical resources, the system needs to have high reliability and ease of maintenance.

3.2 Customized System Design

Adopting evaporative cooling+soft air duct fixed-point air supply scheme, the core includes:

3.2-1 High efficiency evaporative cooling air conditioning unit adapted to Cambodian voltage (230V/50Hz);

3.2-2 Anti corrosion soft air duct network, laid along the main channel of the workshop, with air vents accurately corresponding to the workstation area;

3.2-3 Intelligent control system, which can automatically adjust the air supply volume according to the density of personnel and temperature and humidity in the area;

3.2-4 Low water level protection and water quality filtration device, adapted to local water quality conditions, extends equipment life.

3.3 System Operation Characteristics

3.3-1 Significant Energy Saving: Compared to traditional compressors, it saves more than 70% of energy in refrigeration and alleviates local power pressure;

3.3-2 Targeted cooling: Air supply directly covers the employee activity area, achieving "cooling for people rather than space";

3.3-3 Collaborative Enhancement: The original negative pressure fan is responsible for overall ventilation, while the new system provides cool fresh air, forming a composite effect of "overall ventilation+local cooling";

3.3-4 Quick Installation: Modular structure, complete full line installation and debugging within two weeks, without affecting production plans.

4、 Implementation effect and customer feedback

4.1 Improvement of environmental indicators

After the system was put into operation, the temperature in the job area decreased by 5 ℃ -8 ℃, the relative humidity decreased by 15% -20%, and the employee work area remained within a comfortable range of 28 ℃ -30 ℃.

4.2 Win win situation of production efficiency and humanistic care

The employee turnover rate has decreased, work focus has increased, and the daily output of sewing machines has increased by about 12%;

The occupational health problems such as heatstroke and dizziness have significantly decreased, and employee satisfaction has significantly improved;

The overall improvement of the workshop environment has become a highlight project for the owner to receive customer visits.

4.3 Owner Evaluation

Ruifeng not only provides a set of equipment, but also an overall environmental solution suitable for tropical factories. The electricity bill has not increased significantly, but employees are saying 'it's much better now', which is crucial for us to maintain production capacity and attract workers

5、 Project significance and industry insights

Cambodia and most Southeast Asian countries are currently in a stage of rapid industrialization, with widespread problems such as weak factory infrastructure, tight power resources, and high temperature and humidity environments affecting production. The successful practice of this project has shown that:

5.1 Strong adaptability of Chinese technology: The ability to customize for different countries' voltage, climate, and building characteristics is a key advantage for China's manufacturing industry to go global;

5.2 Energy saving technology is the core competitiveness: In areas with high energy costs, energy-saving air conditioning is not only an environmental equipment, but also a tool for controlling production costs;

5.3 Systematic thinking is crucial: ventilation and cooling are not simply about installing equipment, but should be integrated with building structure, existing systems, personnel flow, and local resources for design.

Relying on the experience accumulated in many domestic industrial scenarios, Ruifeng Environmental Protection Refrigeration is exporting efficient, energy-saving and reliable ventilation and cooling solutions to countries along the "the Belt and Road" to help local industries improve environmental quality and sustainable development capacity.

更多案例

客服热线:18958818969

服务热线:13356130717

电子邮件:ruifeng0717@163.com

公司地址:浙江省温州市平阳县万全镇紫来创业园二幢

瑞峰官网:www.wzrfhb.com